Jungheinrich Dual Fuel Forklift Sacramento

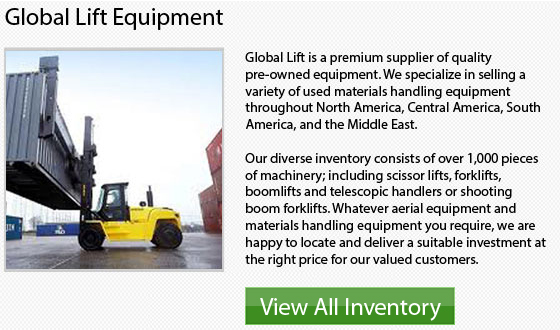

On construction locations all over the world, lift trucks, bulldozers and bobcats have become essential machines. Forklifts are versatile industrial equipment that come in a lot of sizes from fairly small to really huge. They are designed to raise loads and transport materials and products in warehouse or retail environments. Many are designed to easily maneuver within confined, narrow spaces. It takes both ability and training to master a forklift.

The lift truck can be found in nearly every warehouse, factory, and distribution center because they have become vital pieces of machines utilized for handling materials. In warehouses and stockrooms, the lift truck is used to raise and transport merchandise and materials to store them up high. These kinds of equipment are vital for productivity in work settings where there is a large range of stock and a small area to store it in. These trucks are manufactured to transport large pallets around in factories.

Forklift operators in North America are required by law to undergo a training and certification course. This training can be done on the jobsite or in a schoolroom or lecture style setting. Normally training is provided at the workplace. Training and accreditation normally means a pay raise for the person obtaining new skills. Forklifts have standard operating procedures, which makes it easy to get trained on various types of forklifts.

Smaller machines accommodate a single operator in the cab and can maneuver in tight, small areas. The bigger machinery are huge and can carry trucks, automobiles or other types of of equipment. Forklifts could lift thousands of pounds easily.

Typically, construction companies would give salary raises to workers who undergo training. Employers would usually send an employee to classes to train on a large piece of equipment. Willingness to train on a forklift, a bobcat or a bull dozer would pay off.

- Taylor Lifts Sacramento

No matter what kind of business or industry you are a part of, it will be necessary to have a lift truck if you have components or equipment to transport on a consistent basis. Whenever... More - Clark Propane Forklift Sacramento

Power There are numerous types of forklifts which are powered by propane gas. Propane-powered forklifts are easy to refill. The gas is stored in a pressurized tank on the truck's rear. The propane is pushed... More - Terex Straight Boom Lifts Sacramento

What Is a Boom Truck? To recover heavy things or to transport materials to places and areas that are not normally accessible, boom trucks will use a winch. For instance, they are normally used to... More - Terex Loaded Container Handlers Sacramento

Terex's Port Crane division offers experience and unrivaled heritage. This is due to the combination of 2 of the world's best Port Crane manufacturers. The combination of two of the best Port Crane builders within... More - Manitou Duel Fuel Forklift Sacramento

Lift trucks are key pieces of industrial machines for a range of businesses and industries. Numerous thousands of businesses all over the globe would come to a screeching halt if their lift truck was unable... More