Skyjack Scissor lifts Sacramento

How to Calculate Scissor Lift Length

The length of a scissor jack lift is proportional to the scissor support weight together with the integrity of the steel cross sections more than the length. The weight of the scissor structure along with the length is corollaries of each other; thus, the former determines the latter for a stable scissor jack. An extreme instance of this to show the point would be a 20-foot lift length that is featherweight made from Styrofoam which is pretty much weightless. It definitely will not be able to support at much of a height and would not be able to support a lot at all.

In order to calculate the length of a scissor lift, determine how high in the air you have to support a platform that would support of the weight of the occupants and objects on the platform as well as the platform's weight.

The number of cross-sections of scissor folding supports sections that would be necessary to be extended at their full extension to be able to reach the required height within the weight support parameters. Finally, you would never want to ascend some workers up on a platform with their supplies that is on a platform supported by any kind of unstable structure as clearly any type of machinery that is susceptible to tipping would really put individuals in a really dangerous situation.

Every cross section should be weighed to determined the overall weight and length of the scissor lift along with the overall stability of the machinery. When entirely extended, determine the angle between the ground or horizontal level against the scissor arms measured.

- Taylor Lifts Sacramento

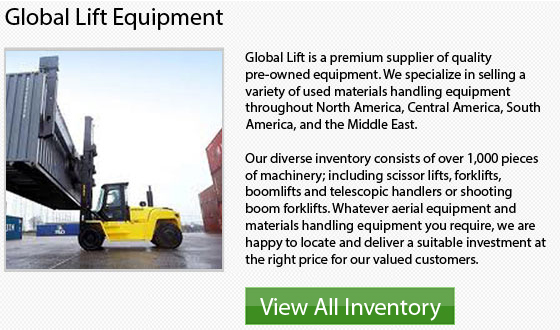

No matter what kind of business or industry you are a part of, it will be necessary to have a lift truck if you have components or equipment to transport on a consistent basis. Whenever... More - Clark Propane Forklift Sacramento

Power There are numerous types of forklifts which are powered by propane gas. Propane-powered forklifts are easy to refill. The gas is stored in a pressurized tank on the truck's rear. The propane is pushed... More - Terex Straight Boom Lifts Sacramento

What Is a Boom Truck? To recover heavy things or to transport materials to places and areas that are not normally accessible, boom trucks will use a winch. For instance, they are normally used to... More - Hyundai Lift Trucks Sacramento

Hyundai Electric and IC forklift trucks offer excellent quality and comfort. Some of the top priorities in the equipment design comprise safety and high durability. There are more than 70 different models of Hyundai Forklifts... More - Manitou Duel Fuel Forklift Sacramento

Lift trucks are key pieces of industrial machines for a range of businesses and industries. Numerous thousands of businesses all over the globe would come to a screeching halt if their lift truck was unable... More