Jungheinrich Double Reach Forklifts Sacramento

Lift truck Material Handling

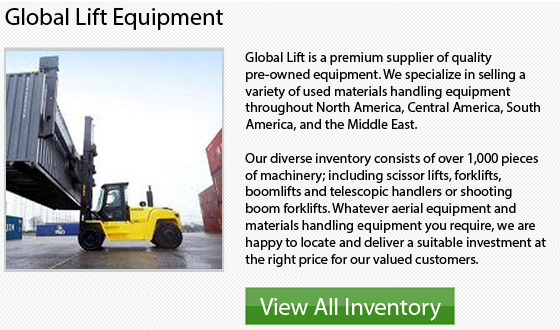

Companies will go through changes in their material handling needs over time. Things such as expanded geographical coverage, additional SKUs, and requirement to lessen inventories demand process review to be able to maintain optimal output. There have been numerous advances within material handling technologies and processes in the past several years. Various tools are evolving at a really fast rate and have the potential to impact productivity a lot.

Forklift Battery & Charging Technology

Now is the perfect time to think about converting from conventional, IC forklifts to electric lift trucks. The technology used in modern electric lift truck battery and charger combinations is well ahead of the technological curve. Electric systems are capable of providing much more power for longer periods than ever before. The new series of electric forklift units offer run-times and capacities that surpass older units. Developments in both charger and battery technologies help contribute to more environmentally sound practices in factories throughout the world.

The lithium-Ion batteries are considered the wave of the future because this key new technology is have a revolutionary effect on the use of electric forklifts. The benefits of Li-ion batteries are run times and low maintenance and size. They could be made in smaller sizes compared to standard lead acid batteries and are capable of holding up to six times the charge. They have zero memory, that allows them to maximize charging.

IC or Electric Forklift

Whether you are replacing an existing truck or looking for your very first forklift, consider investing in an electric forklift. Bear in mind that the technological, legislative and environmental problems involved in forklift technology and usage is subject to change. Kindly review this easy-to-follow guidelines when considering whether an electric or an IC truck best meets your requirements.

- Taylor Lifts Sacramento

No matter what kind of business or industry you are a part of, it will be necessary to have a lift truck if you have components or equipment to transport on a consistent basis. Whenever... More - Yale IC Forklifts Sacramento

Internal Combustion Lift Trucks The Internal Combustion forklift belongs within the class IV and V forklift classification. They can be liquid propane, gas or diesel units. Primarily, the ICE or also referred to as internal... More - Skyjack Knuckle Boom Lifts Sacramento

Boom Truck Boom trucks are quite like cranes and can be equipped with a winch for lifting. This will depend on the weight and size of the vehicle, that determines the type of cargo that... More - Hyundai Lift Trucks Sacramento

Hyundai Electric and IC forklift trucks offer excellent quality and comfort. Some of the top priorities in the equipment design comprise safety and high durability. There are more than 70 different models of Hyundai Forklifts... More - Manitou Duel Fuel Forklift Sacramento

Lift trucks are key pieces of industrial machines for a range of businesses and industries. Numerous thousands of businesses all over the globe would come to a screeching halt if their lift truck was unable... More